STC series measuring grating

STC series measuring grating

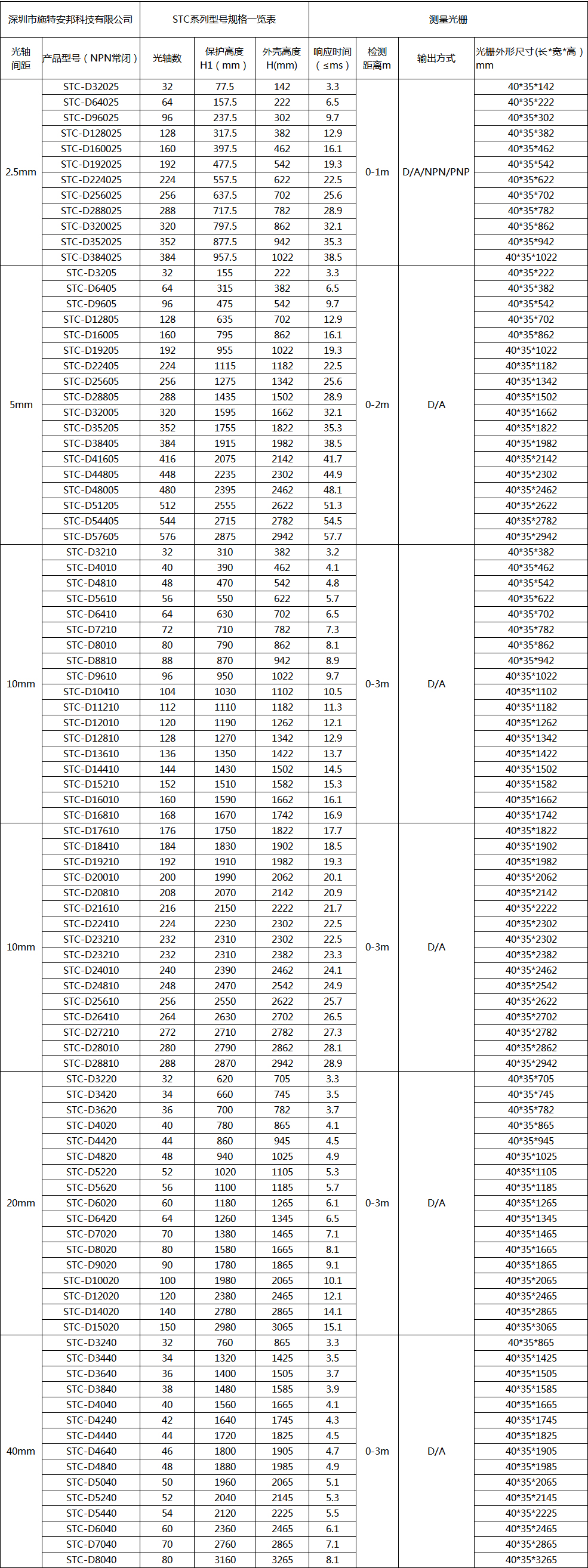

1. Optical axis interval M=5/10/20/40mm, number of beams (points): N=4-330: 46 beams (points), detection range H=1800mm.

2. The shooting distance is 3 meters.

3. RS485 simplex output mode.

4, with two 10 meters long cable.

The

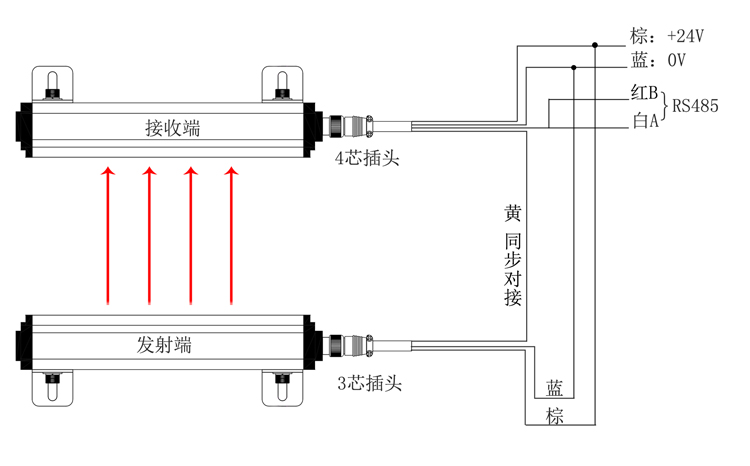

STC measurement grating is composed of a receiving end and a receiving

end. When the infrared light emitted from the transmitting end is docked

with the receiving end, a light curtain is formed. When

an object is placed in the light curtain, a part of the light is

blocked to make the receiving end unable to receive. At this time, the

STC measuring grating calculates the number of the occluded light beam

through the channel scanning, thereby calculating the length or width of

the object. When the scan is completed, a signal

is output according to the system definition. The signal can be an

analog signal or a binary signal. Measuring gratings are now widely used in logistics sorting, product packaging, and automated coating lines.

Features:

※ The shooting distance is up to three meters, and the passing object is strong.

※Different

specifications, inspection accuracy can be customized according to

product conditions, the maximum detection accuracy can reach 2.5 mm.

※

With RS485 communication function, MODBUS protocol can be used to

communicate with the host computer, and the function is free and

flexible.

※The structure design is compact, the section size is only 40*35, the alloy paint shell, the imported process level.

0755-23355724

0755-23355724

社区:

社区: